Call Anytime

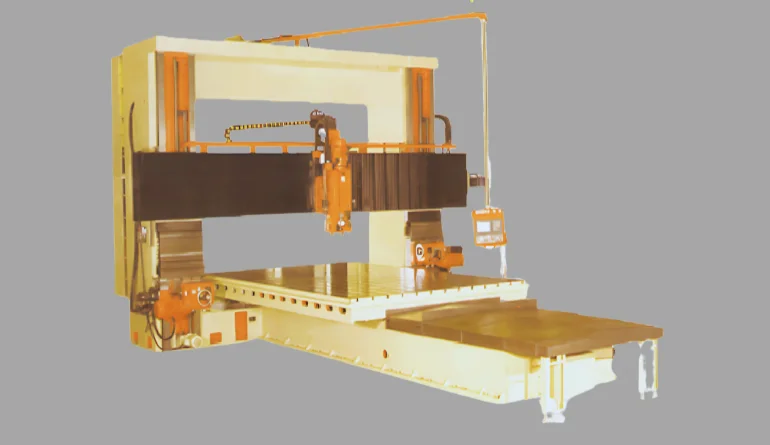

CNC Plano Miller

A CNC Plano Miller is the modern evolution of traditional plano milling machines, integrating advanced Computer Numerical Control (CNC) technology to deliver unmatched precision, repeatability, and productivity. Designed for large-scale milling operations, it is a vital tool in industries demanding complex machining on heavy and oversized components. At Sagar Machine’s India, we offer cutting-edge CNC Plano Millers built for industrial strength and smart control. Our machines are trusted across manufacturing sectors for their rigid design, intelligent automation, and consistently high-quality output. A CNC Plano Miller is a large-scale milling machine where the workpiece remains stationary on a table that moves horizontally, while the tool head moves vertically and laterally to perform multiple machining operations. The CNC system precisely controls all movements, ensuring greater accuracy and efficiency compared to manual or conventional machines. It’s especially suited for tasks like flat surface milling, slotting, contouring, facing, and pocketing on heavy workpieces, such as machine beds, base frames, and structural components in shipbuilding, wind turbines, and heavy engineering sectors.

TECHNICAL DETAILS

| Model | PLM L 4Ft. |

PLM L 5Ft. |

PLM L 6Ft. |

PLM L 7Ft. |

PLM L 8Ft. |

PLM L 9Ft. |

PLM L 10Ft. |

|---|---|---|---|---|---|---|---|

| Distance between columns available in required stroke | (All dimensions in mm unless specified) | ||||||

| Length of Stroke | 1220 | 1524 | 1828 | 2133 | 2438 | 2743 | 3048 |

| Width between columns | 1220 | 1524 | 1828 | 1828 | 1828 | 1828 | 1828 |

| Height under Cross Rail | 1220 | 1524 | 1828 | 1828 | 1828 | 1828 | 1828 |

| Table Specifications | |||||||

| Working Surface Width | 805 | 1060 | 1240 | 1524 | 1524 | 1828 | 1828 |

| No. of T-Slots | 5 | 6 | 6 | 7 | 7 | 9 | 9 |

| Width of T-Slots | 18 | 18 | 18 | 18 | 18 | 22 | 22 |

| Distance between T-Slots | 127 | 148 | 190 | 190 | 190 | 200 | 200 |

| Cross Rail Specifications | |||||||

| Vertical Traverse of cross rail (Elev.) | 1200 | 1500 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Elevating Traverse of side head | 1080 | 1365 | 1600 | 1600 | 1660 | 1600 | 1600 |

| Main Drive | |||||||

| Table Drive Motor | As Per Size of Machine | ||||||

| Cross Rail Elev. Motor | |||||||

| Motor Specification | As Per Size of Machine | ||||||