Call Anytime

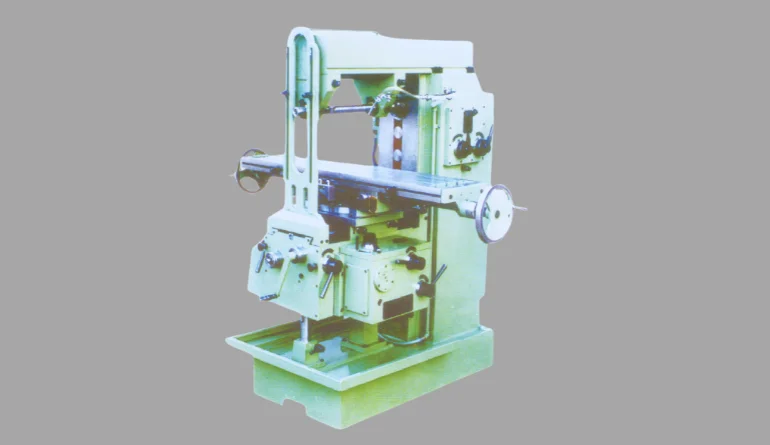

All Geared Universal Milling Machine

A Universal Milling Machine is capable of performing a wide array of operations like gear cutting, slotting, drilling, helical milling, and more. What makes it universal is the ability to tilt and swivel the table to various angles, allowing machining in multiple axes. With all-geared head construction, the machine delivers uniform torque and smooth power transmission through hardened and ground gears, making it ideal for both rough and precision jobs.

Key Features of Sagar’s All Geared Universal Milling Machines

All-Geared Drive Head: Provides a wide range of spindle speeds and feeds through a durable, oil-lubricated gear system, eliminating belt slippage and ensuring efficient performance.

Swiveling Table: The table can be swiveled left or right up to ±45°, allowing angular and helical milling operations with high accuracy.

High Rigidity Body: Built using heavy-duty, stress-relieved cast iron for superior stability, vibration absorption, and longevity.

Precision Slides: Hardened and ground slideways ensure smooth, accurate longitudinal, transverse, and vertical movements.

Vertical & Horizontal Spindle Operation: The dual spindle arrangement supports both vertical and horizontal milling operations, enhancing versatility.

Advanced Lubrication System: Centralized lubrication ensures consistent flow to vital machine parts, reducing wear and increasing lifespan.

Optional Attachments: Includes vertical head, slotting attachment, rotary table, dividing head, DRO systems, and more, enhancing machining capabilities.

Technical Details

| Model | SMU-1.5 | SMU-2 | SMU-3 | SMU-4 |

|---|---|---|---|---|

| Table | ||||

| Working Surface | 1125×250 mm | 1300×275 mm | 1400×325 mm | 1600×350 mm |

| No. & Size of T-Slot | 3×13 mm | 3×13 mm | 3×15 mm | 3×15 mm |

| Distance Between T-Slot | 55 mm | 65 mm | 75 mm | 80 mm |

| Feeds | ||||

| Cross | 200 mm | 230 mm | 280 mm | 315 mm |

| Vertical | 375 mm | 435 mm | 510 mm | 610 mm |

| Longitudinal | 575 mm | 650 mm | 700 mm | 810 mm |

| Spindle | ||||

| Arbor | 25.4 mm | 25.4 mm | 25.4 mm | 25.4 mm |

| Number of Speeds | 9 | 9 | 9 | 9 |

| Number of RPM | 50 to 750 | 50 to 950 | 50 to 950 | 50 to 950 |

| Taper | ISO-40 | ISO-40 | ISO-40 | ISO-40 |

| Distance From Spindle to Top (Min.-Max.) | 10-350 mm | 10-400 mm | 10-500 mm | 10-600 mm |

| Motors (Required) | ||||

| Spindle Motor 1440 RPM | 2 H.P. | 3 H.P. | 3 H.P. | 5 H.P. |

| Coolant Motor 2800 RPM | 0.10 H.P. | 0.10 H.P. | 0.10 H.P. | 0.10 H.P. |

| Vertical Attachment on Ram | ||||

| Cross | 125-350 mm | 135-425 mm | 135-400 mm | 135-535 mm |

| Vertical | 150-435 mm | 100-500 mm | 100-575 mm | 100-625 mm |

| Speeds For Vertical Head (Ram Type) | 6 | 6 | 6 | 6 |

| Weight | 160-425 Kg | 95-550 Kg | 95-550 Kg | 50-450 Kg |

| Net (Approx.) | 1400 Kg | 2000 Kg | 3000 Kg | 3500 Kg |

|---|---|---|---|---|

| Gross (Approx.) | 1600 Kg | 2400 Kg | 3500 Kg | 4000 Kg |

P.I. Note: In accordance with our continuous improvements we reserve the right to change the design, specifications and colour without any notice. Accessories shown in the catalogue are not part of standard equipments.