Call Anytime

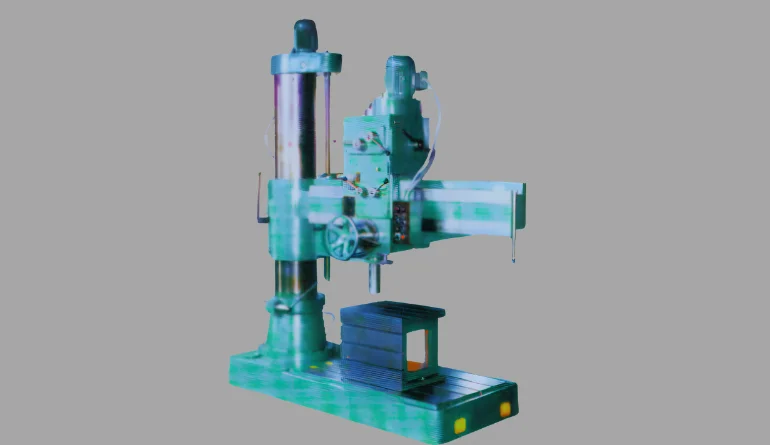

All Geared Radial Drill Machine

All Geared Radial Drill Machine is a robust and highly adaptable drilling solution engineered for precision and durability. Designed for high-volume, heavy-duty operations, this machine is ideal for drilling, boring, reaming, tapping, and counterboring on a wide range of materials—especially large and heavy workpieces. At Sagar Machine’s India, we manufacture top-grade. All Geared Radial Drilling Machines that are widely appreciated across industries for their consistent performance, long service life, and advanced functionality. Built using premium materials and state-of-the-art technology, our machines cater to the demanding needs of workshops, fabrication units, and production floors.

Key Features of Sagar’s All Geared Radial Drill Machine

Gear-Driven Spindle Transmission: Provides multiple speed and feed options through hardened alloy steel gears, ensuring steady torque and performance under heavy loads.

360° Rotating Arm & Adjustable Height: The radial arm can rotate fully and be adjusted vertically, offering flexibility in tool positioning without moving the workpiece.

Hardened and Ground Column & Arm: Ensures durability and vibration-free performance, even during continuous and large-scale operations.

Precision Spindle with Auto-Feed Option: High-accuracy spindle with optional automatic feed ensures consistent depth and finish in every operation.

Wide Speed Range: Multiple speed selections (8, 12, or 16 steps) make it ideal for machining different materials including steel, cast iron, aluminum, and more.

Advanced Lubrication System: In-built centralized lubrication for all major moving parts extends machine life and minimizes downtime.

Heavy-Duty Base & Worktable: Built from stress-relieved cast iron for optimal rigidity and vibration absorption.

Technical Details

| Model | Scale | SDM40 | SDM50 | SDM65 | SDM75 |

|---|---|---|---|---|---|

| Drilling Cap. in M.S.(mm) | A | 40 | 60 | 65 | 75 |

| Drilling Cap. in C.I. (mm) | B | 50 | 60 | 75 | 85 |

| Diameter of Column | A | 255 | 310 | 355 | 405 |

| Drilling Radius Min. | B | 375 | 425 | 650 | 675 |

| Drilling Radius Max. | C | 950 | 1325 | 1600 | 1950 |

| Machine Height Form Floor | D | 2420 | 2760 | 3170 | 3320 |

| Min. Spindle down Position | E | 100 | 100 | 100 | 100 |

| Min. Spindle up Position | F | 1150 | 1300 | 1600 | 1750 |

| Drilling Depth | G | 160 | 225 | 325 | 325 |

| Working surface of base plate | F | 885 x 545 | 1150 x 655 | 1460 x 845 | 1735 x 940 |

| Dimension of Base (R x S x T) | F | 1470 x 705 x 180 | 1755 x 835 x 200 | 2370 x 1015 x 210 | 2640 x 1110 x 210 |

| Effecarea of box table (L x K x M) | F | 330 x 330 x 330 | 600 x 450 x 450 | 600 x 450 x 450 | 600 x 450 x 450 |

| No. of spindle speed & Range (RPM x Step) | F | 45-660 x 6 steps | 40-790 x 9 steps | 25-930 x 12 steps | 20-740 x 12 steps |

| No.of spindle speed & Range (Rev. x Step) | 0.095 - 215 x 3 steps | 0.080 - 180 x 3 steps | 0.10 - 0.125 x 6 steps | ||

| Taper spindle nose socket | MT 4 | MT 5 | MT 5 | MT 6 | |

| Main Motor | 2 HP | 3 HP | 5 HP | 7.5 HP | |

| Elevating Motor | 1 HP | 2 HP | 3 HP | 5 HP | |

| Weight of Machine (approx.) kg | 2000 | 3200 | 4800 | 6500 |