Call Anytime

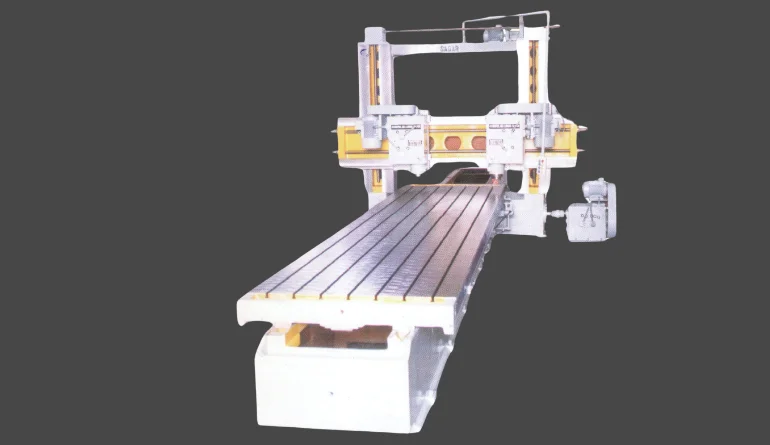

Heavy Duty Plano Miller

A Heavy Duty Plano Miller is a highly advanced and robust machine tool designed to perform precise milling operations on large and heavy components. Built to handle intense workloads, this machine is essential for industries where accuracy, durability, and consistent performance are critical. At Sagar Machine’s.India, we manufacture and supply world-class Heavy Duty Plano Millers engineered to meet the diverse needs of heavy industries such as power generation, aerospace, shipbuilding, and steel fabrication. Our machines are trusted across India and overseas for their superior build, long service life, and top-tier machining capabilities.

Key Features of Sagar’s Heavy Duty Plano Miller

Robust Structure: Constructed with heavy-duty cast iron and stress-relieved components, our machines ensure exceptional stability and vibration resistance.

Powerful Milling Heads: Equipped with high-performance horizontal and vertical milling heads that can be operated simultaneously for multi-axis machining.

Large Work Table: Heavy-duty precision-ground table ensures smooth and accurate movement for heavy components, with excellent load-bearing capacity.

Precision Feed Mechanism: Automatic and manual feed systems allow controlled movement for accuracy in every cut, with variable feed options for different jobs.

Gear Driven System: Our gear-driven milling heads are built for torque-heavy operations with smooth transmission and minimum backlash.

Column and Cross Rail Adjustability: The cross rail can be adjusted vertically to accommodate different component heights, while columns provide high rigidity during operation.

Hydraulic and Electrical Controls: Easy-to-use hydraulic clamping systems and intuitive electrical controls ensure user-friendly operations and safety.

TECHNICAL DETAILS

| Model | PLM L 4Ft. |

PLM L 5Ft. |

PLM L 6Ft. |

PLM L 7Ft. |

PLM L 8Ft. |

PLM L 9Ft. |

PLM L 10Ft. |

|---|---|---|---|---|---|---|---|

| Distance between columns available in required stroke | (All dimensions in mm unless specified) | ||||||

| Length of Stroke | 1220 | 1524 | 1828 | 2133 | 2438 | 2743 | 3048 |

| Width between columns Height under Cross Rail |

1220 | 1524 | 1828 | 1828 | 1828 | 1828 | 1828 |

| Table Specifications | |||||||

| Working Surface Width | 805 | 1060 | 1240 | 1524 | 1524 | 1828 | 1828 |

| No. of T-Slots | 5 | 6 | 6 | 7 | 7 | 9 | 9 |

| Width of T-Slots | 18 | 18 | 18 | 18 | 18 | 22 | 22 |

| Distance between T-Slots | 127 | 148 | 190 | 190 | 190 | 200 | 200 |

| Cross Rail Specifications | |||||||

| Vertical Traverse of cross rail (Elev.) | 1200 | 1500 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Elevating Traverse | 1080 | 1365 | 1600 | 1600 | 1660 | 1600 | 1600 |

| Table Speeds | |||||||

| No. of speeds | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Range of speeds | 0.049, 0.067, 0.1 | 12.122 | - | - | - | - | - |

| Feed Gear Box for Milling Head Cross Traverse | |||||||

| No. of cross Traverse | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Range of Cross | 0.038, 0.054, 0.1 | 0.38 | - | - | - | - | - |

Note: In accordance with our continual improvements we reserve the right to change the design, specifications and colour without any notice. Accessories shown in the catalogue are not part of standard equipments.